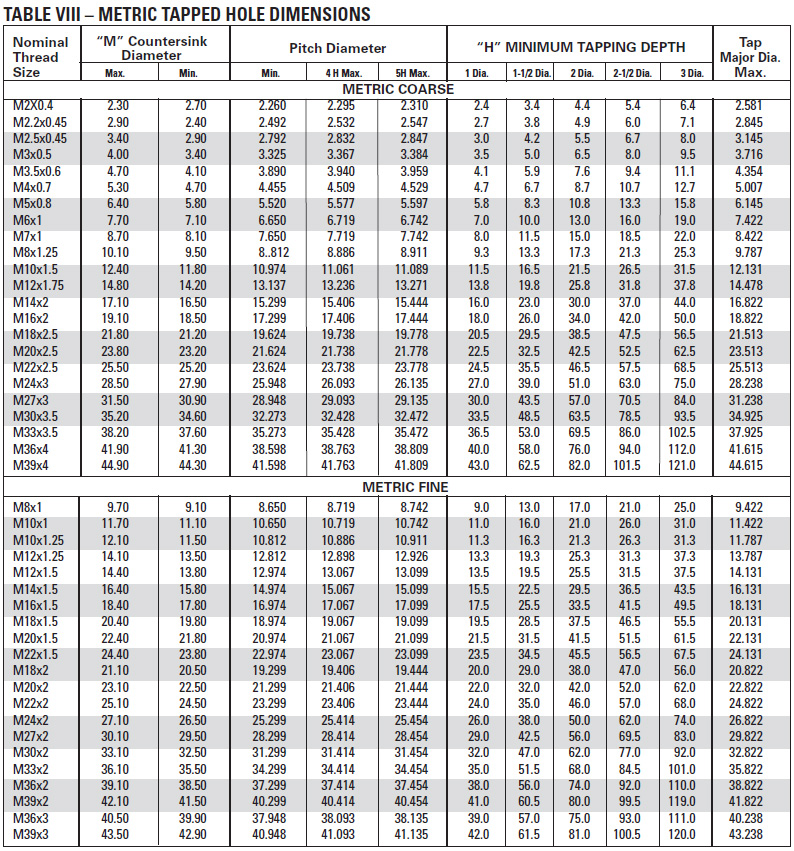

The material will have to be cut and pushed out in order to create a thread in that hole. So, if we wanted to drill a hole for our example bolt, we would need to use a drill that is smaller than 4 mm. Finally, 20 is the length of the bolt in mm, measured from the tip of the thread to the bottom of the head (with the exception of oval headed bolts). The second number (0.7) is the pitch which corresponds to the distance between two adjacent threads in millimeters. The “M” indicates the “metric diameter” of its thread (see tap drill chart below), which in our case is 4 mm. Bolts are classified by specification codes such as:. Having determined the bolt that we want to use in the specific case, we already have a technical specification for the thread which will host it. Thread Geometry And Drilling The HoleĪs is evident from the above, to create the thread we first need to drill a hole on the workpiece.

If the taper needs to go first, the intermediate tap follows second and the thread is finished with the bottoming tap. This minimises the risk of damaging the drilled hole.

The taper tap features a smooth diameter transition that allows for a less aggressive cutting action. The taper tap is only used in certain situations such as when the material is very hard or the hole is too small. However, the bottoming tap cannot start the threading on an uncut hole, so it can only take part in the cutting process as the second or third tap. So next comes the bottoming tap that has the capacity to do this. Unfortunately, due to the shape it can’t create a thread all the way to the end of the hole. That is why it features a tapered bit, allowing the machinist to align it correctly. The intermediate, or plug tap, is used first to start cutting out material from a non-threaded hole. To create a thread properly, one would need a set of three taps that correspond to the same bit size namely the bottoming, the intermediate, and the taper tap. Therefore the tap drill chart is extremely important. The following recommendations apply for minimizing the effects of corrosion on Heli-Coil ® stainless steel insert assemblies at operating temperatures less than 800☏ and using carbon steel or alloy steel bolts.As you would expect, taps come in all forms and sizes in order to accommodate standardised screw threads. The effect of corrosion on threaded assemblies is dependent on many factors: This allows for the design of assemblies where the bolt will fail before the parent material.Īssembly strength is a function of shear area and the shear strength of both the bolt and parent material.įor detailed charts on specific load values, Heli-Coil ® Technical Bulletin 68-2 (inch) covers the complete range of sizes, parent materials, and bolt strengths. This choice of insert length balances the bolt tensile strength against the shear strength of the parent material. In the Heli-Coil ® catalog (HC2000), the lengths are listed as multiples of the nominal thread diameter of the screw 1, 1-1/2, 2, 2-1/2, and 3. Heli-Coil ® offers maximum design flexibility while adhering to conservative engineering practice, allowing use of Heli-Coil ® inserts in virtually any application.įive lengths of inserts are available.

0 kommentar(er)

0 kommentar(er)